Pickle Robots automate loading and unloading trucks - one of the most difficult human logistics tasks where staff turnover is typically more than 100%.

It’s hot in the summer and cold in the winter, and the boxes always seem to get heavier. Injuries are common. Costs are increasing and staff is harder to find. Our robotic system reliably unloads 400 to 1,500 cases per hour depending on the freight.

Solve Labor Challenges

Automates trailer and container unloading with minimal human supervision.

Improve Your Throughput

Reliably operates at 600+ PPH today, allowing you to reallocate your workforce to other bottlenecks within your building.

Get a Safer Work Environment

Reduces potential injury from heavy and repetitive lifting, enabling compliance with labor regulations and lowering staff turnover.

Reliable

We use the most reliable commercial industrial components and proven secure software then back it up with world-class support and maintenance.

Handles Variety

Operates in loose-packed environments, and handles packages of many shapes and sizes.

Retrofittable

Can be used with any power or gravity flex conveyor. Trailers do not need to be modified.

Fits Most Trailers

Will work in any trailer or ocean container that is between 72"x90”x10’ and 99”x110”x53’.

Unloads Fast

Systems reliably achieve 600+ PPH in production deployments with minimal staff supervision.

Mobile

Easily moved from dock to dock and sets up in <10 minutes. Mobile base advances deeper into Trailer automatically: simply press ‘Go’.

FEATURED NEWS

PICKLE ROBOT

Pickle Robot, Jun 24, 2025

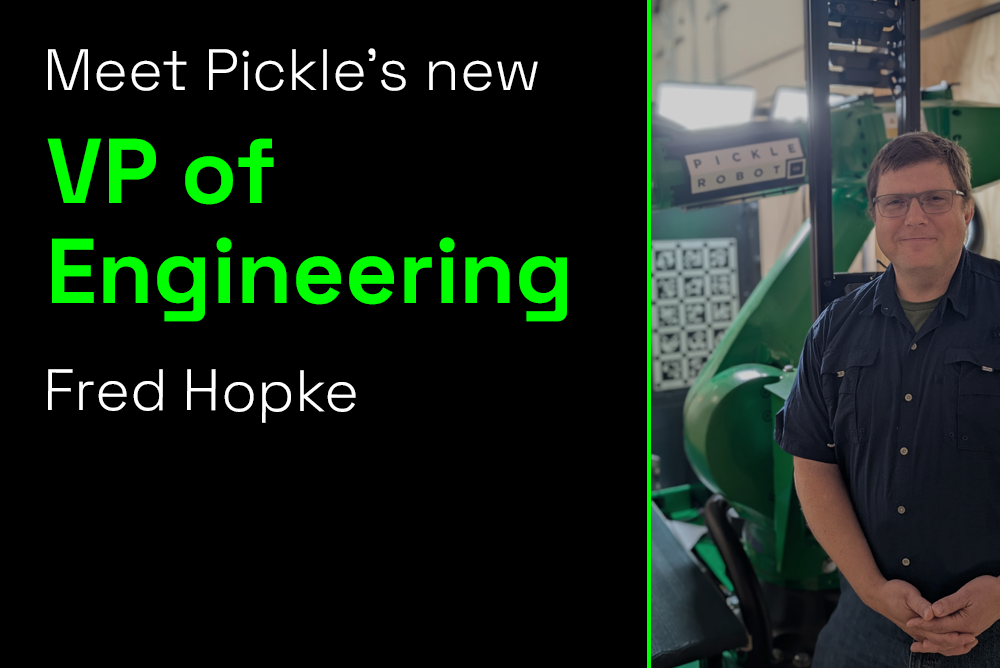

Today we announced Fred Hopke as our new Vice President of Engineering and unveiled plans to hire 50 additional engineers over the next four months. The strategic expansion supports rapid growth in customer demand and deployment of Pickle’s intelligent robotic systems across logistics operations.

PICKLE ROBOT

Pickle Robot, Nov 19, 2024

Read more about our latest Series B raise, with participation from a strategic customer, Teradyne Robotics Ventures, Toyota Ventures, Ranpak, Third Kind Venture Capital, One Madison Group, Hyperplane, Catapult Ventures, and others.

CUSTOMER NEWS

Pickle Robot & Randa, Jan 8, 2025

Pickle Robot has been in production at Randa’s Fort Worth Logistics fulfillment center since mid-October unloading containers of products. So far, the Pickle Robot has unloaded over 1.5 million pounds of apparel, including pants, shirts, and accessories.

Have questions?

Request information from one of our team members.

We are happy to answer any questions, and discuss how Pickle can help your business.

Privacy Policy

Terms of Use

Copyright © 2025 Pickle Robot Company. All rights reserved.